Mines for electric car metals in Congo strain workers’ health, families

FUNGURUME, Democratic Republic of Congo — Alain Kasongo, burly and goateed, worked for four years driving the heavy trucks that hauled away tons of cobalt ore from a gaping hole at one of the biggest mines in Congo. The vibrations from the equipment and the jolts of driving over rough ground during his 12-hour shifts could be bone-rattling, he said. Finally, the pain in his spine grew so unbearable that he needed surgery.

His older brother, Patchou Kasongo Mutuka, worked the same job at the same mine. He suffered the same injury and required the same surgery — as did 13 other drivers of excavators and trucks at the mine who were interviewed. They lifted their shirts to reveal surgical scars and spread out carefully folded medical records confirming their accounts. They in turn named seven more colleagues who had suffered the same fate, all within a two-year period.

“It hurt so badly when I went home, I would lie awake at night,” said Alain Kasongo, 43, displaying bumps and ridges on his body from what he said were three operations.

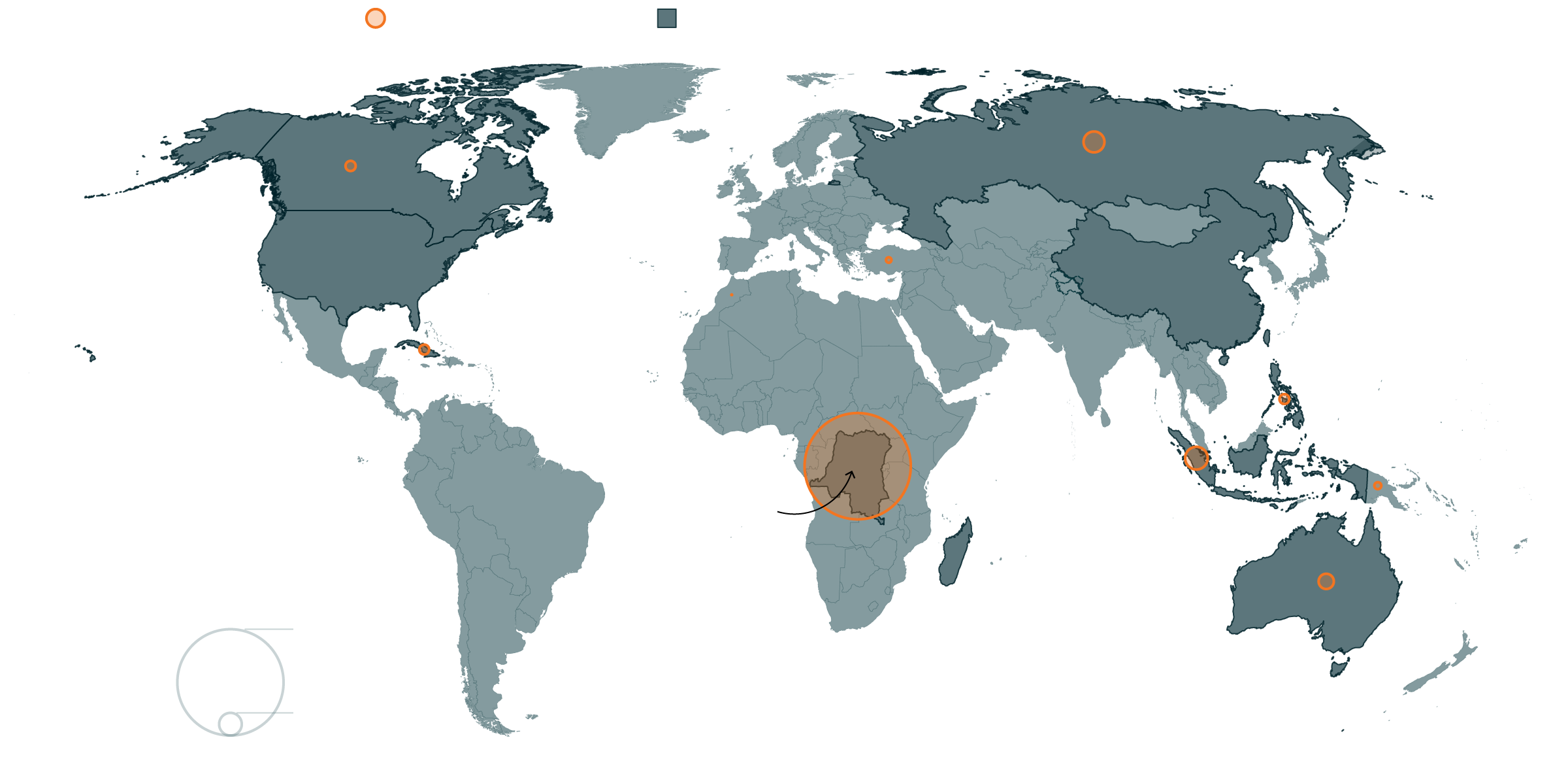

The pressure to produce cobalt is tremendous. It is an essential ingredient in the batteries of most electric vehicles and many consumer electronics. And the Democratic Republic of Congo, or Congo for short, is the king of cobalt. Last year, it accounted for about three-quarters of global production, according to Benchmark Mineral Intelligence. This cobalt can come at a high human price.

Seven years ago, revelations about dire working conditions in Congo’s informal mining sector vaulted into the world’s headlines after Amnesty International and the Congolese rights group Afrewatch published a report detailing deaths and injuries among the countless children working in small-scale, hand-dug mines, often in manually carved tunnels that frequently collapsed and buried the young miners alive.

Since then, global appetite for Congo’s cobalt has grown sharply, mostly driven by a dramatic increase in the demand for EVs. Nearly 90 percent of the cobalt produced in Congo, home to half the world’s reserves, goes into batteries, including those used by American, French, German, Japanese and South Korean automakers. Demand for cobalt is projected to increase 20-fold by 2040, according to the International Energy Agency.

Top cobalt-

producing countries

Countries with the

largest known reserves

Democratic

Republic of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

Top cobalt- producing countries

Countries with the largest known reserves

Democratic

Republic of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

Top cobalt-producing countries

Countries with the largest known reserves

Democratic

Republic of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

Top cobalt-producing countries

Countries with the largest known reserves

Democratic

Republic of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

Top cobalt-producing countries

Countries with the largest known reserves

Democratic

Republic of Congo

The largest known

cobalt reserves are in

the Democratic Republic

of Congo

EVs are widely considered crucial to addressing climate change. Their adoption is spreading at a breakneck pace, fueling soaring demand for minerals including cobalt, lithium, nickel and manganese that go into building EV batteries and the overall vehicles. But the extraction and processing of these metals, in far-flung parts of the world, often take a significant and largely unrecognized toll on workers, local communities and the environment.

Without a full accounting, there is a risk that the green-energy transition could repeat the painful history of earlier industrial revolutions.

The Amnesty report about cobalt mining in Congo and the widespread press coverage that followed prompted the industries that produce and use cobalt to set voluntary standards for the responsible sourcing of the mineral. Many automakers now say they use suppliers that are audited for adherence to these standards and that use cobalt only from mechanized industrial mines, where child labor is forbidden.

Clean cars, hidden toll

A series unearthing the unintended consequences of securing the metals needed to build and power electric vehicles

These industrial mines accounted for about 89 percent of Congo’s cobalt production in 2020, according to a study by the U.S. Geological Survey, although industry insiders said some smaller industrial mines buy hand-dug ore and include it in their tallies. The very biggest mines, operated by companies such as Swiss-owned Glencore and China Molybdenum (CMOC), say they do not buy any ore from hand-dug mines, which are known as artisanal mines. Former employees, artisanal mine bosses and residents who live near the mines said in interviews they believe that’s true, noting that it would be hard to conceal truck convoys transferring ore from hand-dug mines.

But unsafe, artisanal mining persists, as does child labor. In locations visited by Washington Post journalists, workers in flip-flops and torn T-shirts, including some who appeared to be teenagers, crowded into huge open pits or descended into the tunnels that honeycomb the ground. Their ore is usually bought by middlemen and smaller industrial mines, refined locally and then shipped to China, where it disappears in the opaque global supply chain.

Yet even industrial mining can be hazardous. In interviews, 36 current and former employees at nine of Congo’s industrial cobalt mines described the dangerous work done every day. Some said their employers treated injured workers well and offered alternative jobs, but many told of workers who suffered life-changing injuries on the job and then were either fired or saw their medical bills rejected, in what they contend was a violation of Congolese law.

Patrick Kazadi Mumba, a neurologist in the mining town of Lubumbashi, has treated hundreds of miners. He said he knew of at least 150 heavy-machine operators — the drivers of large trucks and excavators — who needed spinal operations in the past decade, almost all for herniated disks. They accounted for half his patients.

“I was seeing very young people with spinal problems,” he said, calling the rate of injury “very unusual.” Most of the injured operators who were interviewed for this article were in their 30s and 40s when they underwent surgery.

Mumba said the number of those injured is likely to be far greater than those he has seen, since many mine workers seek treatment only when their disks or vertebrae are so damaged that they need operations. Some miners conceal their injuries until they become unbearable so they can continue working. The cases aren’t limited to the Tenke Fungurume mine, where Alain Kasongo and his brother worked — owned by CMOC, the world’s second-biggest cobalt producer — but are common across Congo’s industrial mines, he said.

Heavy-machine operators say they are exposed to constant, strong vibrations for long periods, both day and night, as they work 12-hour shifts with only one break, six days in a row. Some countries recognize such vibrations as a medical risk that must be managed. The operators are also subjected to frequent jolting, they say, as they drive their heavy vehicles along uneven dirt tracks.

Julie Liang, CMOC’s vice president for environmental, social and corporate governance, said the company has adopted several measures to protect the health of heavy-machine operators. The condition of their seats is checked to see if they vibrate, and if they do, the operators are to stop their work immediately so that maintenance teams can examine the seats and replace them if necessary, she said. The company also checks to make sure that roads in the pit are smooth so that the trucks do not jolt or vibrate, and trucks are to be loaded initially with soft material so that heavier boulders don’t make the truck jolt, she said.

During the past seven years, the company’s occupational health department has reported that 28 heavy-machine operators have undergone back surgery, according to Liang. The mine currently employs 534 operators.

“Ensuring responsible mining practices, including the health and safety of mineworkers, is essential for the industry future,” said Susannah McLaren, head of responsible sourcing and sustainability at the Cobalt Institute, an industry body. She said companies are encouraged to follow principles and guidelines set by the United Nations, the International Labor Organization and the Organization for Economic Cooperation and Development.

But Gregory Mthembu-Salter, an expert on Congolese mining who founded South Africa-based Phuzumoya Consulting, which researches African political economies and natural resources, said international concern about mining conditions, so focused on child labor, has overlooked threats to the safety and rights of workers in the industrial mines.

“How can you base a green revolution on trashing Congolese environment and exploiting Congolese workers?” he asked.

Life-changing injuries

Congo — chaotic, corrupt and mired in poverty despite glittering riches below ground — straddles Africa’s cobalt and copper belt. Highways in the southeast of the country are choked with trucks hauling sacks of midnight-blue cobalt hydroxide powder and stacked plates of burnished copper, two key metals for the global transition to cleaner energy.

Most major EV manufacturers use cobalt that is at least in part sourced from the Tenke Fungurume mine, according to mapping by Brussels-based Resource Matters, which studies the management and impact of mining.

In the town of Fungurume, men in reflective nylon jackets shout greetings across the dusty streets during shift changes. Pickup trucks sporting the mine’s orange flags weave through traffic. Small shops showcase gleaming spades and pickaxes.

The mine is the town’s lifeblood. But fortunes can quickly change.

All 15 of the injured heavy-machine operators who were interviewed said the mine paid for their medical care and spinal operations and kept them on full salaries while they recuperated, as required by Congolese law. They all received doctor’s notes, reviewed by The Post, saying they could return to work in duties that did not entail heavy lifting or exposure to intense vibration.

Instead, they said, the mine let nearly all of them go.

Without work, most lost their homes. Some saw their families break up. Others had to pull their children out of school.

Alain Kasongo’s employer, CMOC, had promised him different duties, he said — a relief because he had a wife and 12 children to support. But after he had finished recuperating from surgery, he said, he was abruptly told he had no more job. He said he was given $9,000, about six months’ pay, as severance.

Kasongo said that when he could no longer pay school fees, the headmaster reprimanded his children in front of an assembly and expelled them. The youngest children ran home in tears. To help pay for the oldest two to finish school and graduate, his wife began skipping meals and medication.

“It’s so painful. I wish I could die,” he said, ducking his face inside his neckline to wipe away an angry tear. “I don’t sleep. I’m the father. I should provide.”

Mwambe bin Nkongolo said he returned to the mine after his surgery, but CMOC would not give him a different job, despite a medical note. He said he resumed his old duties and worked for three months until severe pain and the fear of crippling himself led him to quit. He left behind a scathing letter of complaint.

Liang said CMOC’s policy is to give new, suitable jobs to employees who have been injured until they’re able to return to their original work. If a worker is permanently unable to resume their original job, the company tries to “reallocate the employee in line with his or her current abilities,” she said. When that fails, after six months of sick leave, the employee can be legally fired on “grounds of unfitness,” Liang added.

Some have tried to find alternative work in other mines, but they said their scars meant they couldn’t pass medical exams to get hired.

“Who will employ me like this?” asked Christian Mutamba Njenge, who recounted receiving injected painkillers for two years before undergoing spinal surgery and losing his job. Since then, his wife has left him, taking their children.

Claims of paltry compensation

Similar stories about poor treatment were repeated in interviews with current and former workers who had been injured at industrial mines scattered across southeastern Congo. But the nature of the injuries varied widely. Many of these employees spoke on the condition of anonymity for fear of retaliation.

One worker, whose fingertip was severed by a machine, said his supervisor dumped him at the entrance of the mine while he was still bleeding, leaving him to find a taxi to get to the hospital by himself.

Another worker said his wages were slashed by two-thirds as he recovered after a badly soldered pipe sprayed him in the face with acid.

Yet another recounted that his family had to save up money to have metal pins removed from his leg after a workplace injury because the company wouldn’t cover the cost.

In one of the mining towns, in a cluster of crumbling houses on an alley choked with flattened plastic bottles and chicks scrambling underfoot, lives a worker who tried to fight for his rights.

Now 30, the man was injured a couple of years ago while working for a subcontractor at one of the country’s largest mines. He had been trying to repair a machine, he said, when his supervisor pressed the wrong button and accidentally unloaded a pipeful of cement into his face.

The worker said he suffered permanent damage to his eyes that required surgery and three months of recuperation. When he went to collect his paycheck, he was fired and told that even the salary for the last month he had worked — $150 — was being withheld to help cover the costs incurred by the company for his medical treatment.

The worker recounted filing a court case, seeking $9,000 in damages. The clerk asked him for $50 to make a company representative appear in court. He paid but nothing happened. Then he went to the government labor office, which asked him for $350 to open a case. He didn’t have it, so he borrowed it. But when his wife developed breast cancer, the money went for her operation instead, he said.

Broke, he couldn’t even afford to buy formula for his 8-month-old daughter, he said. The baby came down with a fever and died.

“Her name was Mirene,” his wife said softly.

Josué Kashal, a human rights lawyer who runs the Centre d’Aide Juridico-Judiciaire, began bringing workers’ cases against the industrial mining companies in 2019. His office is in the boomtown of Kolwezi, where concrete walls topped with razor wire bisect the huge tawny steppes of mining waste towering over the city. Kashal has a filing cabinet full of cases. Progress is slow. Many of his clients just give up.

One of his clients is Jean Ngoy Kazadi, a former security guard at the Pumpi mine, which belongs to Chinese-majority-owned Lamikal. Kazadi was shot during a robbery at the mine early last year. One of his legs had to be amputated.

Eighteen months later, he says, his employer, a subcontractor called Balto, still won’t pay the medical bill. So the hospital is detaining him until the bill is paid — a common practice in African medical centers to ensure that debtors don’t abscond. Each day, the bill increases $20, and it recently topped $10,000. It’s more than he ever made at the mine.

Thierry Alamba, who runs Balto, said, “Our lawyer wants to negotiate with [the hospital]. It is very expensive for us.” He referred further questions to Balto’s lawyer, who did not respond. Lamikal did not respond to requests for comment.

Kazadi, 43, a father of six children, is desperate. “I’ve got no salary, no food; my kids don’t go to school,” he said dolefully as he shuffled along the tiled floor toward his room. He spends his afternoons sitting just inside the hospital’s freshly painted white fence, staring at the sun-drenched, bougainvillea-lined street just out of reach.

Subcontracted workers at risk

Kazadi’s predicament is common, according to doctors interviewed in three of Congo’s largest mining towns, especially among workers employed by subcontractors for the mining companies.

The large companies usually pay a stipend to help cover health care for workers and their families, the doctors said, though the amount and quality of health care varies from mine to mine. But a 2021 report by Rights and Accountability in Development (RAID), a London-based corporate watchdog group focused on Africa, said that about 57 percent of workers in the five largest mines in Congo are employed by subcontractors. Compared with those directly employed by the mining companies, these workers are usually paid less and don’t receive the same benefits, the group said.

“Subcontracted workers often lack the basic minimum requirements for health and safety, and they earn extremely low wages,” said Anaïs Tobalagba, a legal and policy researcher for RAID. “Many lack basic protective equipment and, when injured, are fired because their employers simply don’t want to pay for medical care or are only willing to pay an insignificant amount.”

To avoid bringing employees directly onto their payroll, as required by law, mining companies often switch among subcontractors when those firms’ short-term contracts expire.

The employees of some subcontractors said in interviews that they were often expected to work for months without a day off and that their pay would be docked if they took one. One man said he had worked 14 straight months at the Tenke Fungurume mine without a weekend off.

In this case, Liang said, the subcontractor’s policy was to give its workers four days of paid leave each month.

Asked about the general treatment and hours of subcontractors’ employees at Tenke Fungurume, Liang said, “The subcontractors have and implement their own policies and we ensure, through due diligence and onsite monitoring, that they comply with the law and do not contradict CMOC policies.” She added: “All employees and contractors are made aware of the complaints hotline and encouraged to report violations. The company has appropriate procedures in place for investigating and dealing with reported violations.”

Under Congolese law, employers are required to pay for the treatment of workers injured on the job, and employees are entitled to two consecutive days off after seven days of work.

Perilous artisanal mining persists

In the years after Amnesty’s revelations, the very largest mining companies moved to insulate their ore from that dug by hand in the small-scale mines. These big companies operate their own on-site cobalt refineries to prevent any mixing.

But some smaller companies do buy directly from the artisanal mines. Or, at local refineries, these companies mix their machine-excavated ore with hand-dug ore from artisanal mines. This cobalt eventually finds its way into the international supply chain.

At some of the hand-dug mines, workers load the ore onto the back of motorbikes or into vans that haul it to depots run by middlemen, locally known as “negotiateurs.” The largest of these depots is at Musompo, where the nicknames of negotiateurs, such as “Boss Djo” and “Madame Wu,” are scrawled across battered sheet-metal signs in front of the stalls.

Other artisanal mines, such as Shabara, strike direct deals with companies whose trucks rumble into the pits and carry off sacks of ore, or with local refineries that process it for export.

Despite the furor over child labor and treacherous working conditions, eliminating the artisanal mining sector would be a disaster because it supports about 200,000 miners and their families, said Jacques Kaumba Mukumbi, the mining minister for Lualaba province.

In recent years, the Congolese government, foreign companies and the industry-funded Fair Cobalt Alliance have sought to work with the cooperatives that run some artisanal mines to improve their conditions. But the money required to enhance safety is scarce.

SAEMAPE, the government-backed union charged with monitoring safety in the hand-dug mines and ensuring that tunnels don’t exceed 30 meters (just under 100 feet) in length, is so poorly funded that staffers often have to pay motorbike taxis out of their own pockets to travel among the sites, according to a SAEMAPE representative who spoke on the condition of anonymity to be candid.

RCS Global, an auditing firm partly funded by Western multinational companies, monitors six artisanal mining sites, and its recommendations have helped improve safety and reduce child labor, according to data provided by the group. But these mines still recorded 65 deaths between the start of 2019 and this May, the data shows. The most durable safety measures, such as using machinery to clear away earth that can collapse into tunnels, are expensive, said Nicholas Garrett, director of RCS Global. So accidents remain common.

In June, such a tunnel collapse at the Midingi mine trapped 35-year-old Fiston Ngoy wa Nyembwe. When the earth began to shift, his fellow miners scrambled to the surface, but he was the deepest in the tunnel and couldn’t escape.

For 18 days, he had no light or food, and no one heard his screams. “I thought I would die,” he said from a hospital bed. “I prayed a lot. I thought about my family.”

Ultimately, workers digging for ore nearby broke through the wall of his tunnel and were shocked to discover him alive, lying on the ground, too weak to move. He had survived on moisture dripping through the tunnel walls, a fellow worker said.

He was dragged to the surface — his eyes bandaged against the unfamiliar light — to cheers that echoed around the pits.

About this story

Check out our Latest News and Follow us at Facebook

Original Source